Inside a workshop there are craft, industrial or repair activities where the temperature of the working environment is crucial to ensuring that the work is done properly. Especially during the cold seasons, understanding how to heat a workshop is vital to be able to work well and safely.

How to heat a workshop

Workshops can vary greatly from one another, precisely because of the different nature of the work that takes place in them; that is why it is not possible to say with certainty which method is best for heating a workshop. However, workshops usually have an open, or partially open structure, with high ceilings and wide doors, in order to allow specialised vehicles to enter. They may contain various tools or machine tools that compromise air quality due to high smoke and dust production.

Heating a working environment with these characteristics is by no means a matter of course; it is necessary to ensure an internal temperature that is as constant as possible and that does not, in most cases, involve open flames or sparks. In addition, the method chosen also depends on the size of the workshop, the type of activity performed and the climatic conditions outside.

Here are the main heating systems for a workshop:

Gas heating

This method involves the use of a gas burner to generate heat, which is then diffused into the room via a ducting system. This is usually a fairly inexpensive system to install, but with extremely fluctuating costs depending on gas prices.

In addition, the costs of securing the workshop and the low yield of heating in workshops with high heat loss must be considered.

Electric heating

Electricity can be used to generate heat in a very specific area of the room or to heat the air to be distributed later through diffusers. An electric heating system is easy to install and adjust, it is quite efficient – because it converts almost all energy into heat – and is relatively safe compared to other heating systems.

The most common disadvantages of heating a workshop with an electric heating system are the large spaces that are poorly insulated thermally, where maintaining a constant temperature becomes very difficult, leading to a significant increase in costs.

Heat pump heating

A heat pump heating system is able to concentrate heat inside the workshop by utilising the energy in the air, or in the groundwater.

These types of systems are energy efficient, use renewable resources and tend to have lower consumption costs. They can also be used to cool the workshop in summer, offering great flexibility.

However, it is not possible to install a heat pump heating system in every room, because it requires specific climatic conditions to work properly. There are also very high installation and maintenance costs, which are not affordable for most workshops.

Infrared heating

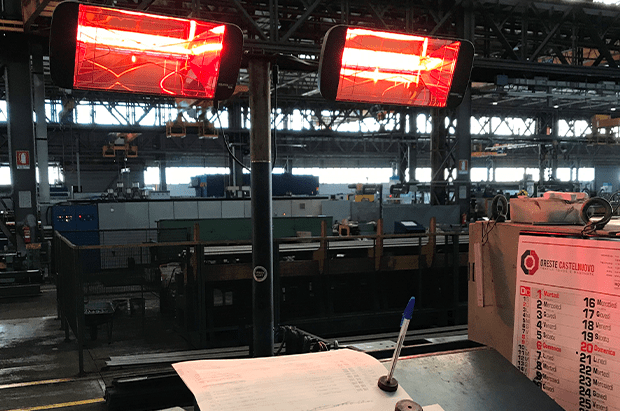

An infrared heating system is able to emit heat by using the ability of infrared waves to warm the surfaces of objects and people they come into contact with, but without heating the air directly.

Infrared heating systems are ideal for efficiently heating even large workshops, with one or more outdoor sections or with particularly high ceilings. Their ability to heat surfaces directly ensures a good balance between the energy emitted and the heat produced, heating the room quickly and safely. The main disadvantage of infrared heating systems is their limited coverage, since they are only capable of heating a very specific portion of the room.

Is it really worth heating a workshop with an infrared system?

Infrared heaters are an excellent, economical and safe alternative for heating a workshop, providing immediate heat and avoiding wasted energy. Compared to conventional heating systems, infrared heaters offer numerous advantages:

- Targeted heating: an infrared heating system only heats objects and people in the room, without heating the air and creating moving air currents, preventing dust from rising and keeping the air cleaner.

- Local Warming approach: the best infrared heaters are able to activate only for as long as necessary and only where required, thanks to the Local Warming approach.

- Quiet: infrared heaters are very quiet and are suitable for extended use in any workspace.

- Immediate heating: infrared heaters generate heat almost instantaneously, providing immediate thermal comfort.

- Eco-sustainability: the technology used in infrared heating systems emits neither fumes nor pollutants into the air – because it does not burn fuels to generate heat – so they can be powered by renewable energy sources.

- Smart regulation: the best infrared heating systems allow you to regulate the temperature with great precision, even via smartphone.

- Safety: they are suitable for work environments where it is necessary to generate heat safely, preventing the risk of fire.